Practical Measurement

There are a number of methods for correcting emissivity in order to obtain the true temperature. The correction procedure with each method will be explained next. But note that this procedure is unnecessary when the emissivity is already known.

(1) Method of comparison or direct measurement with emissivity at nearly 1

[1] Unify the temperatures of the measured object or similar material.

[2] Open a very small hole (hereafter called blackbody part) in the object which the ICI IR Monitor can detect so as to satisfy the blackbody conditions.

[3] Then set the emissivity correcting function of camera so the temperature of the blackbody part and the measured surface will be the same. The obtained emissivity will be the emissivity of the measured surface.

[4] Thereafter when measuring found the same conditions, it is unnecessary to change the emissivity setting.

(2) Method of direct measurement of emissivity

If a hole cannot be made as in [1], then apply black paint or the like and carry out the same procedures to obtain the emissivity. But since the black paint will not provide a perfect blackbody, first set the emissivity of the black paint and then measure the temperature.

(Refer to Fig. 5.1 Examples of blackbody paint)

(3) Indirect measurement

Make a sample similar to the measured object, and place it in a condition able to be heated by a heater, etc. Then measure the object and the sample alternately with the camera and when the indicated values are identical, measure the sample with a contact-type thermometer. This enables measuring the temperature indirectly.

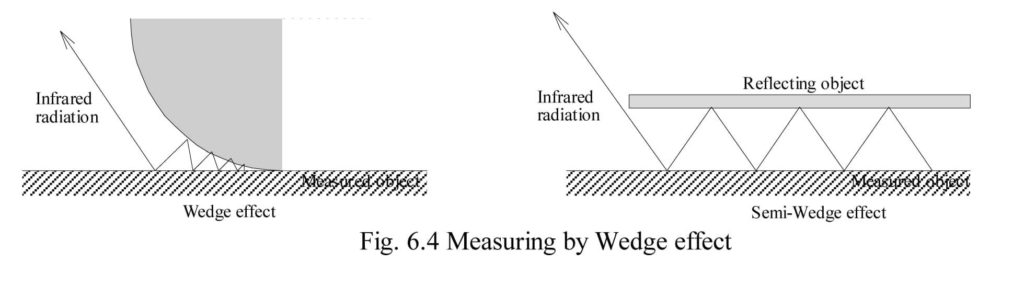

(4) Measuring by Wedge effect

With this method, the emissivity of the measured surface itself is enhanced through use of the wedge or semi-wedge effect. But one must be careful about the number of reflections and/or the measuring angle.